Fleksibilne poliuretanske pene

Fleksibilne poliuretanske pene su jedna od najvažnijih klasa ćelijske plastike koja se koristi u proizvodnji materijala kao što su sunđeri, memorijske pene, jastuci, nameštaj, materijali za oblaganje za automobila, pakovanje, obuća itd. Procenjena je ukupna potrošnja fleksibilne poliuretanske pene na preko 7 miliona tona u 2007. godini, a prosečna godišnja stopa rasta je oko 5%. Uopšte, industrije koje proizvode fleksibilne poliuretanske pene koriste punila da modifikuju svojstva materijala na određeni način kako bi postigla dimenzionalnu stabilnost lako povlačenje iz kalupa i gustinu servisiranja. Proizvodni trošak fleksibilne poliuretanske pene značajno zavisi od troškova poliola, koji predstavljaju najveći procenat materijala koji se koriste u proizvodnji pene sa karakteristikama da induciraju vrhunska mehanička svojstva. Pogodna punila koja su relativno jeftina mogu se uneti u matricu pena kao zamena za poliol. Uticaj CaCO3 punila u fleksibilnoj matrici od poliuretanske pene za dvostruke svrhe postizanja održivih mehaničkih svojstava i smanjenja troškova proizvodnje. Nađeno je da je optimalni sastav CaCO3 20 mas.% Što predstavlja istovremeno smanjenje troškova proizvodnje od 18,54%. U fleksibilnim poliuretanskim penama punila promovišu povećanje gustine i otpornosti na kompresiju.

Proizvodi :

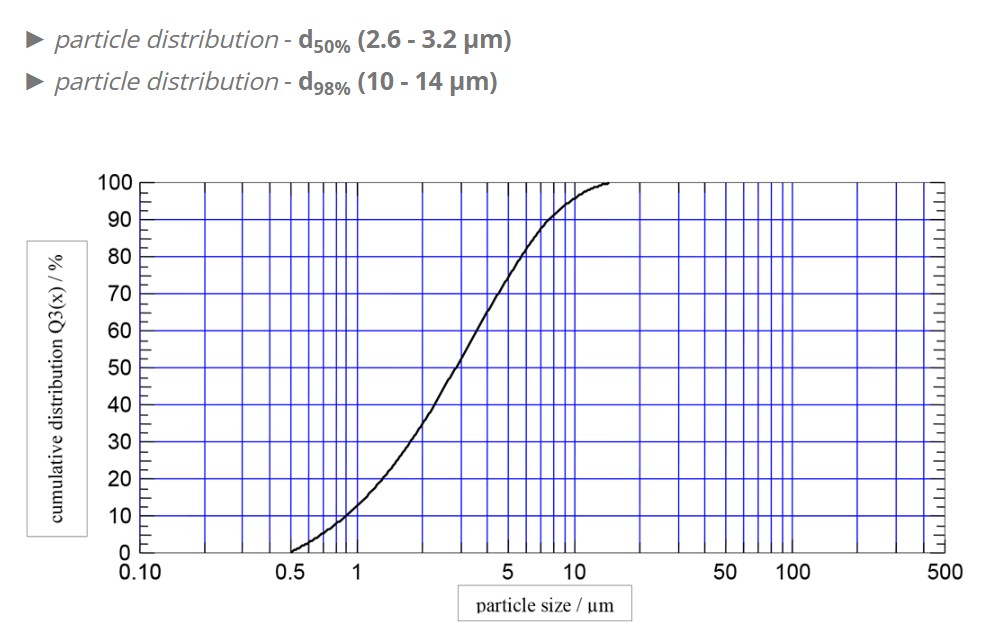

Ducalcit 2

Ducalcit 2 je izrazito fin prah dobijen mlevenjem prirodnog kalcijum karbonata dobro poznatog po svojoj visokoj hemijskoj čistoći.

Tehnički list - Ducalcit 3

Tehnički list - Ducalcit 3

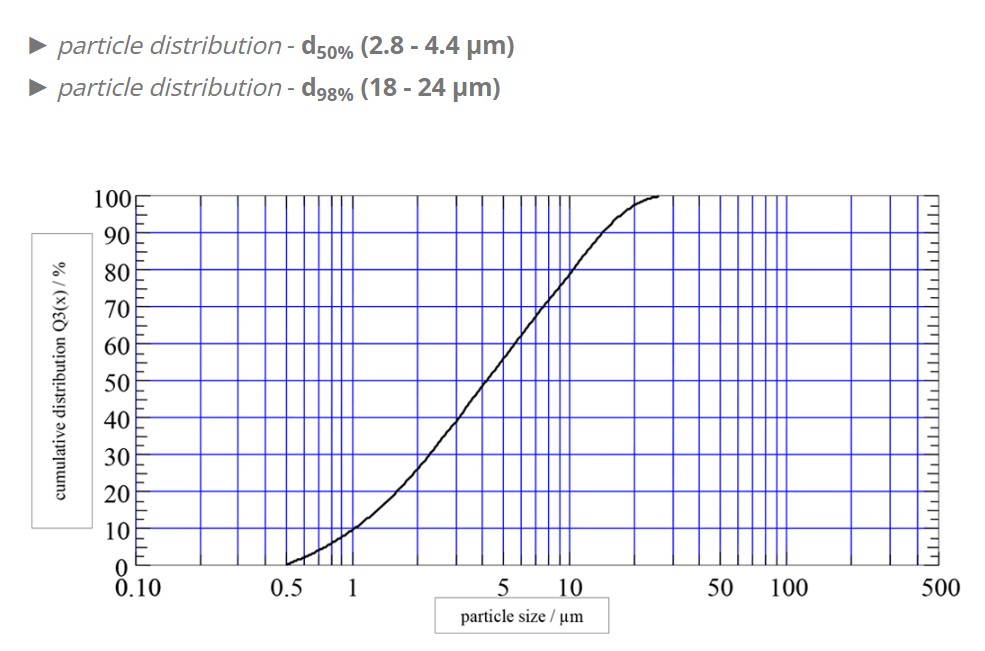

Ducalcit 5

Ducalcit 5 je izrazito fin prah dobijen mlevenjem prirodnog kalcijum karbonata dobro poznatog po svojoj visokoj hemijskoj čistoći.

Tehnički list - Ducalcit 5

Tehnički list - Ducalcit 5